NICKEL SILVER

Kiyomine Metal Industry has developed the HCR series of nickel silver alloys, which exhibit resistance to heat discoloration even after being exposed to 300°C for 10 minutes, based on many years of research and proven experience.

NICKEL SILVER

Kiyomine Metal Industry has developed the HCR series of nickel silver alloys, which exhibit resistance to heat discoloration even after being exposed to 300°C for 10 minutes, based on many years of research and proven experience.

Nickel Silver Alloy Lineup

Kiyomine's nickel silver refers to alloys with a wide compositional range: Cu 50–70%, Ni 5–35%, and Zn 15–35%.

Within this range, higher Ni content improves spring properties. Higher Zn content increases strength but reduces toughness.

Thanks to its excellent strength and spring characteristics, nickel silver is used in electronic components such as shield cases and electrical contacts. Its beautiful silvery-white appearance and outstanding corrosion resistance also make it widely used in high-end tableware, decorative items, and brass instruments.

Furthermore, based on long-standing research and experience, Kiyomine has developed the HCR series of nickel silver alloys, which exhibit heat and discoloration resistance even under conditions of 300°C for 10 minutes.

| Application | General Use | Heat Discoloration Resistance | |||||

|---|---|---|---|---|---|---|---|

| Product Name | C7701 | C7521 | C7541 | C7451 | HCR-C7701 | HCR-C7521 | |

| Chemical Composition [wt.%] | Cu | 55 | 64 | 62 | 65 | 56 | 64 |

| Ni | 18 | 18 | 14 | 10 | 18 | 18 | |

| Zn | 27 | 18 | 24 | 25 | 26 | 18 | |

Heat Discoloration Resistant Nickel Silver HCR-C7701, HCR-C7521

Nickel silver is a ternary alloy composed of copper (Cu), nickel (Ni), and zinc (Zn). In general, higher Ni content enhances spring properties, Zn increases strength, and Cu contributes to ductility, resulting in excellent workability and mechanical properties.

Among these, C7521 is widely used for applications such as shield cases. Components made from this alloy are typically exposed to temperatures above 250°C for around 5 minutes during soldering in atmospheric environments. Under such conditions, discoloration often occurs, and affected parts are regarded as visually defective.

To address this technical issue, Kiyomine optimized the processing conditions for C7521, successfully improving its resistance to discoloration at 250–300°C for 5 minutes.

Thanks to this outstanding heat discoloration resistance, the improved materials have been designated as Heat Discoloration Resistant Nickel Silver C7701 and C7521, abbreviated as HCR-C7701 and HCR-C7521.

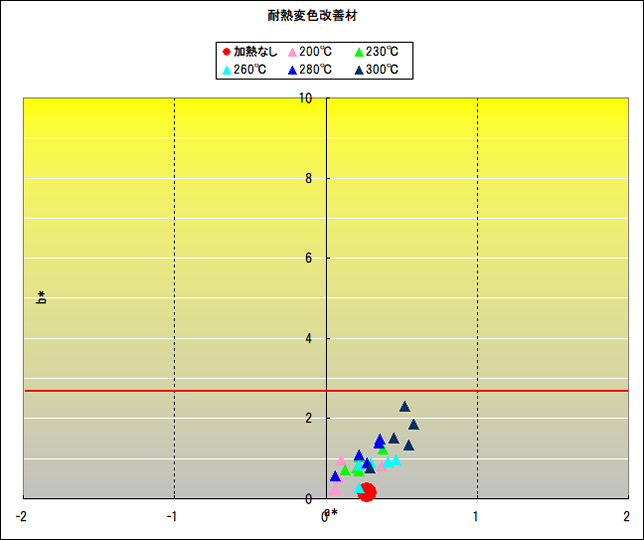

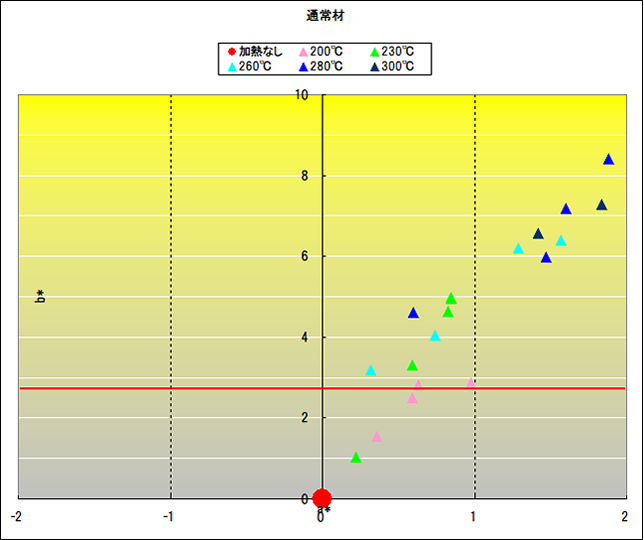

Heat Resistance Test Results

Since perception of discoloration varies from person to person, we quantified the color for evaluation.

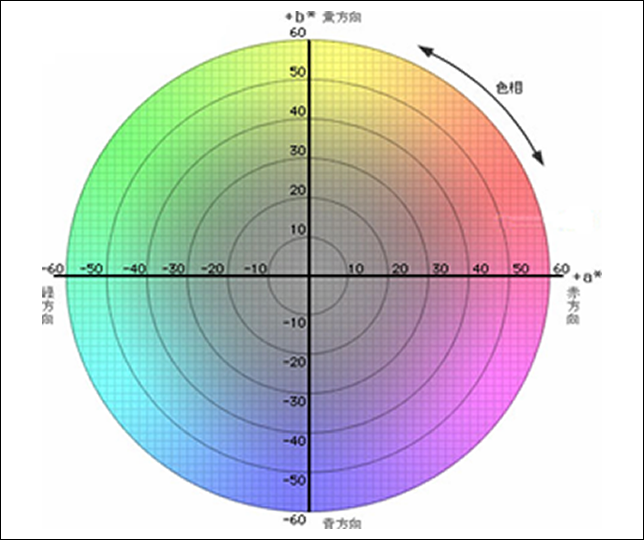

The assessment was based on the L*a*b* color space, as defined in JIS (JIS Z8729).

In this system, L* represents lightness, a* indicates red on the positive side and green on the negative side, and b* indicates yellow on the positive side and blue on the negative side (see Figure 1).

As the values increase, the colors become more vivid.

- *1 : A color difference of 3 units or more in a* or b* is generally considered perceptible to the human eye. Crossing the specified threshold (red line) is regarded as discoloration.

- *2 : The condition before heat treatment is designated as the baseline (0) in accordance with JIS terminology.

Composition and Properties Overview

Chemical Composition

| Product Name | Nickel Silver | HCR-Nickel Silver | |||||

|---|---|---|---|---|---|---|---|

| Alloy Name | CDA No. | C77000 | C75200 | C75400 | C74500 | C77000 | C75200 |

| JIS No. | C7701 | C7521 | C7541 | C7451 | HCR-C7701 | HCR-C7521 | |

| Chemical Composition [wt.%] | Cu | 54.0-58.0 | 62.0-66.0 | 60.0-64.0 | 63.0-67.0 | 54.0-58.0 | 62.0-66.0 |

| Zn | Rem | Rem | Rem | Rem | Rem | Rem | |

| Fe | -0.25 | -0.25 | -0.25 | -0.25 | -0.25 | -0.25 | |

| Ni | 16.5-19.5 | 16.5-19.5 | 12.5-15.5 | 8.5-11.0 | 16.5-19.5 | 16.5-19.5 | |

| Sn | - | - | - | - | - | - | |

| P | - | - | - | - | - | - | |

| Si | - | - | - | - | - | - | |

| Mn | -0.5 | -0.5 | -0.5 | -0.5 | -0.5 | -0.5 | |

Physical Properties

| Product Name | C7701 | C7521 | C7541 | C7451 | HCR-C7701 | HCR-C7521 |

|---|---|---|---|---|---|---|

| Melting Point [℃] | 1055 | 1060 | 1075 | 1020 | 1055 | 1060 |

| Poisson's Ratio | 0.32 | 0.32 | 0.32 | 0.34 | 0.32 | 0.32 |

| Specific Gravity | 8.7 | 8.73 | 8.68 | 8.61 | 8.7 | 8.73 |

| Electrical Conductivity [%IACS] | 5.5 | 6 | 7 | 9 | 5.5 | 6 |

| Thermal Conductivity [W/m・K (20℃)] | 29 | 33 | 38 | 46 | 29 | 33 |

| Elastic Modulus [GPa] | 125 | 125 | 125 | 121 | 125 | 125 |

| Coeff. of Thermal Expansion [ppm/K (20~300℃)] | 16.7 | 16.2 | 16.2 | 16.4 | 16.7 | 16.2 |

Mechanical Properties

| Product Name | C7701 | C7521 | C7541 | C7451 | HCR-C7701 | HCR-C7521 | |

|---|---|---|---|---|---|---|---|

| Tensile Strength [MPa] | O | - | 375- | 355- | 325- | - | 375- |

| 1/4H | - | - | - | - | - | - | |

| 1/2H | 540-655 | 440-570 | 410-540 | 390-510 | 540-655 | 440-570 | |

| H | 630-735 | 540-640 | 490- | - | 630-735 | 540-640 | |

| EH | 705-805 | 610- | - | - | 705-805 | 610- | |

| SH | 765-865 | - | - | - | 765-865 | - | |

| ESH | - | - | - | - | - | - | |

| XSH | - | - | - | - | - | - | |

| 0.2% Proof Strength [MPa] | O | - | - | - | - | - | - |

| 1/4H | - | - | - | - | - | - | |

| 1/2H | 390- | - | - | - | 390- | - | |

| H | 500- | - | - | - | 500- | - | |

| EH | 600- | - | - | - | 600- | - | |

| SH | 680- | - | - | - | 680- | - | |

| ESH | - | - | - | - | - | - | |

| XSH | - | - | - | - | - | - | |

| Elongation [%] | O | - | 20- | 20- | 20- | - | 20- |

| 1/4H | - | - | - | - | - | - | |

| 1/2H | 8- | 5- | 5- | 5- | 8- | 5- | |

| H | 4- | 3- | 3- | - | 4- | 3- | |

| EH | - | - | - | - | - | - | |

| SH | - | - | - | - | - | - | |

| ESH | - | - | - | - | - | - | |

| XSH | - | - | - | - | - | - | |

| Vickers Hardness [HV] | O | - | - | - | - | - | - |

| 1/4H | - | - | - | - | - | - | |

| 1/2H | 150-210 | 120-180 | 110-170 | 105-155 | 150-210 | 120-180 | |

| H | 180-240 | 150-210 | 135- | - | 180-240 | 150-210 | |

| EH | 210-260 | 185- | - | - | 210-260 | 185- | |

| SH | 230-270 | - | - | - | 230-270 | - | |

| ESH | - | - | - | - | - | - | |

| XSH | - | - | - | - | - | - | |